3D Printing News Unpeeled: Blended FDM

Description

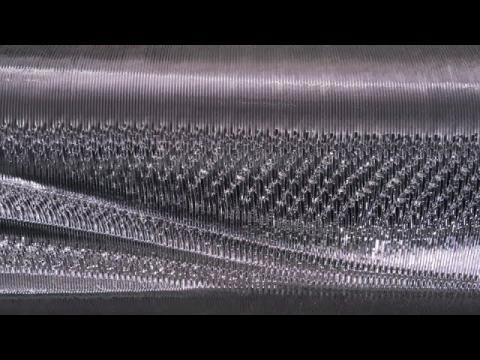

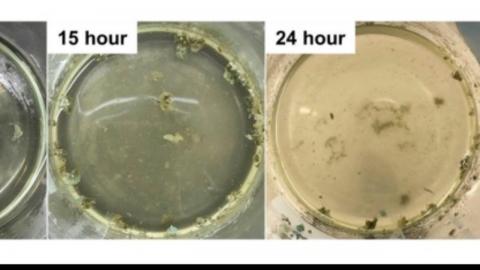

Just published in Nature, a paper by a Seoul National University team looks at, ¨3D printing with a 3D printed digital material filament for programming functional gradients.¨ Sang-Joon Ahn, Howon Lee, Kyo-Jin Cho show how they extrude and print filament to mix gradients of properties. By using the 3D printer itself to blend the filament they can then print it again to dial in more properties. By doing this in two different steps their ¨blended FDM¨ approach can change mechanical strength, conductivity and other properties.

A team of fellowship students working with Titan Dynamics looked at iterating and improving 3D printed drones. The team took 22.5 hours to assemble six craft at Elgin.

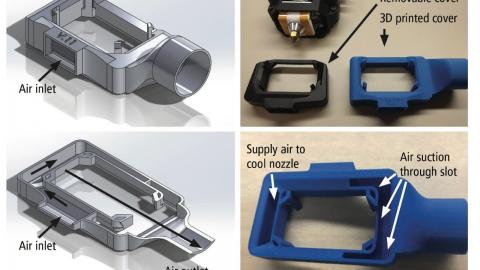

A Queen 1 3D printer from Q.Big was used to make a cockpit for a flight simulator. The project by Reiser Simulation and Training GmbH and Murtfeldt Additive Solutions GmbH printed the unit in a month. The longest print time took 100 Hours. Usually it would take three to six months to make a similar component conventionally. The unit was printed in 25% PA GF on a granulate printer that can vary nozzle diameter.

Comments