3D Printing News Unpeeled: Inconel Wire DED and a $52,000 Metal 3D Printer

Description

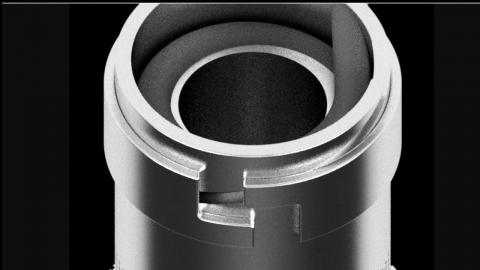

The Defiant200 by Defiant3D, is a £40,000 ($52,000) 3D printer that uses Cold Deposit and Sinter Technology. This uses vibration to deposit powder and support powder. The printer itself is then used as a vacuum sintering oven. The part needs no conveyancing and also the support powder has a higher melting point than the build powder meaning that it will stay a powder. The build volume is 200 x 200 x 200mm, it has its own slicing software and current uses 316L steel that comes in a container. The method could eventually lead to fewer green state parts collapsing and more efficiency. The price point is very low and this is a new approach to metal printing that could very well have legs.

Ross Stevens and Nicole Hone have worked together to make the Power Pot Plant a wind turbine inspired by plants. The turbine is simple and printed in PLA. We should be seeing many more larger scale objects like it going forward.

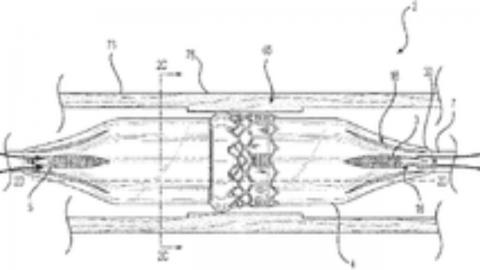

Norsk Titanium and QuesTek Innovations LLC are working together on commercializing Nickel alloy wire DED. This could lead to lightweight economical parts using 3D printing for aviation, cars, oil and gas and more. The duo are trying to Devine the right settings and heat treatment for the process.