Injection Molding Design Tips (to avoid common defects)

Description

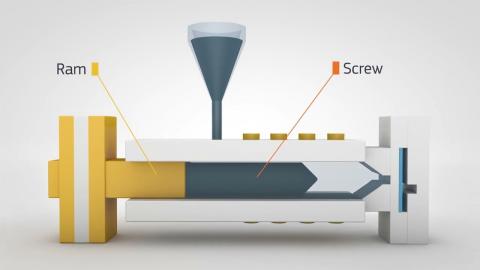

#injectionmolding In this video, we’re going to talk about 6 design tips to help you avoid the most common issues in injection molding. Avoiding common defects in injection moulding is important because mold production is costly and you don't want to redesign the parts of your mold.

Get a FREE injection molding quote here: http://3dhu.bs/zlbPeU

00:00 Introduction to injection molding design tips to avoid common defects.

00:22 Tip 1: Add draft angles to your injection moulding parts.

00:45 Tip 2: Avoid undercuts in your part design.

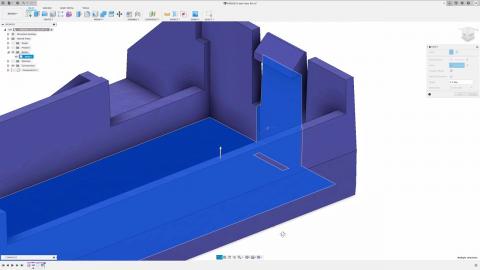

01:07 Tip 3: Attach bosses, ribs, or side walls.

01:32 Tip 4: Use a constant wall thickness or add smooth transitions.

01:55 Tip 5: Hollow out thick sections and add ribs.

02:19 Tip 6: Rounding all edges in your injection molding part design.

02:48 Summarisation of all the design tips.

03:06 Conclusion

Hubs is an online manufacturing platform that provides engineers with on-demand access to a global network of manufacturing partners. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Facebook: http://3dhu.bs/R-OXDm

Instagram: http://3dhu.bs/7EZ5mG

Twitter: http://3dhu.bs/oRC1uy

LinkedIn: http://3dhu.bs/t2KEyM