3D Printing News Unpeeled: 3D Printed Data centers, Ceramics for the US Army

Description

A subsidiary of SINTX Technologies has signed a Cooperative Research and Development Agreement (CRADA) with the U.S. Army Combat Capabilities Development Command Army Research Laboratory (DEVCOM ARL) for ceramics 3D printing and ceramic matrix composites (CMCs). The company makes ceramics components for the military and is a 3D printing ceramics service as well as a manufacturer of filled materials. It also makes body armor and armor for the US military. The company also will look at high temperature components using pyrolysis and other means. These kinds of things could be used for extended life barrels, engines, missiles and better fitting body armor for example.

The Kraus Group has completed the Wavehouse Campbell Heidelberg for Heidelberg iT Management a 100 rack data center in Heidelberg Baden-Württemberg. Not coincidentally the home of Heidelberg cement. The 600 square meter property was made with Cobod BOD2 printers with help from Peri3D. Im excited at future thermally efficient datacenter buildings for capturing and removing heat well. This could really make a difference.

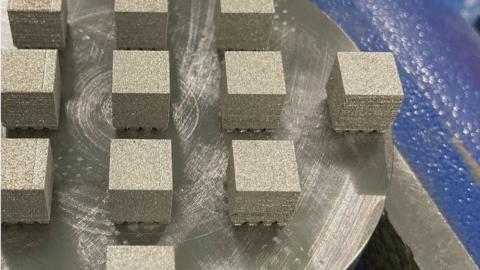

Eplus has come out with an optional one to four fiber laser machine that lets you choose between 500W, 700W or 1KW per laser, the EP M400S. Such optional printers, if they present an upgrade path and they can be made efficiently by the OEM could really present a huge battleground for the future of powder bed fusion for metals. They're the most efficient platform for most production and if people can be persuaded to buy a single laser one first for development and then seamlessly upgrade it then it will be a winner for OEMs. The 400 by 400 by 450 mm build volume printer has a bidirectional recoater and comes with feeding and powder recycling units and this time is top loaded.